Nanoparticle Breakthrough: Mass Production Method Could revolutionize Ovarian Cancer Treatment

April 4, 2025

Targeted Drug Delivery: A game-Changer for Cancer Patients

For decades, the brutal reality of chemotherapy has been a double-edged sword: attacking cancerous cells while concurrently wreaking havoc on healthy tissue. But what if drugs could be delivered directly to tumors, minimizing side effects and maximizing effectiveness? Polymer-coated nanoparticles loaded with therapeutic drugs are offering just that promise, especially in the fight against ovarian cancer, a disease that will affect an estimated 1 in 78 women in the U.S. during their lifetime.

Researchers at MIT, in collaboration with the Scripps Research Institute, have announced a significant leap forward in this field. Led by MIT Institute Professor Paula Hammond and Scripps Research Institute professor Darrell Irvine, the team has developed a new manufacturing technique that dramatically increases the production speed and volume of these targeted nanoparticles. This breakthrough, detailed in the journal Advanced Functional Materials, could pave the way for wider clinical trials and, ultimately, more accessible and effective cancer treatments for American patients.

Layer-by-Layer: The Art of Nanoparticle Engineering

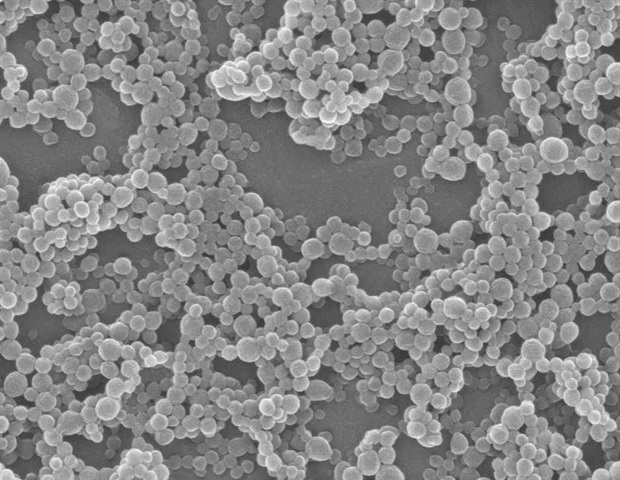

Over the past decade, Hammond’s lab has pioneered the use of layer-by-layer assembly, a technique that allows for the creation of nanoparticles with highly controlled architectures. Imagine building a microscopic Lego structure, where each layer possesses distinct properties and functionalities. This approach involves alternately exposing the nanoparticle surface to positively and negatively charged polymers, creating layers that can be embedded with drug molecules, targeting molecules, or other therapeutic agents.

these targeting molecules act like GPS systems, guiding the nanoparticles to specific cancer cells. once they reach their destination,the drug payload is released,directly attacking the tumor while sparing healthy tissues. This targeted approach is particularly crucial in treating cancers like ovarian cancer, which often spreads throughout the abdominal cavity, making it difficult to target with traditional methods.

From Lab to Production: Overcoming Manufacturing Bottlenecks

While the initial layer-by-layer assembly technique proved effective in mouse studies, scaling up production for human use presented a significant challenge. The original process involved applying one layer at a time, followed by a time-consuming centrifugation step to remove excess polymer. “There’s a lot of promise with the nanoparticle systems we’ve been developing, and we’ve been realy excited more recently with the successes that we’ve been seeing in animal models for our treatments for ovarian cancer in particular,” says hammond. “Ultimately, we need to be able to bring this to a scale where a company is able to manufacture these on a large level.”

Even the introduction of tangential flow filtration, a more streamlined purification method, still faced limitations in terms of manufacturing complexity and maximum production scale. As Hammond noted, although the use of tangential flow filtration is helpful, it’s still a very small-batch process, and a clinical examination requires that we would have many doses available for a significant number of patients.

The new manufacturing technique addresses these bottlenecks head-on.

Microfluidics: A Revolution in Nanoparticle Manufacturing

The breakthrough lies in the use of a microfluidic mixing device. This device allows researchers to sequentially add new polymer layers as the particles flow through a microchannel. The key is precise calculation: researchers can determine exactly how much polymer is needed for each layer, eliminating the need for purification after each addition.

“That is really significant because separations are the most costly and time-consuming steps in these kinds of systems,” Hammond explains. This innovation streamlines production, reduces the risk of human error, and integrates Good Manufacturing Practice (GMP)-compliant processes, which are mandated by the FDA to ensure product safety and consistency.

GMP compliance is crucial for bringing new drugs to market in the U.S. It ensures that manufacturing processes are well-controlled and documented, minimizing the risk of contamination, errors, and variations in product quality. The fact that the microfluidic device used in this study is already used for GMP manufacturing of mRNA vaccines further strengthens the potential for rapid translation of this technology into clinical applications.

According to Ivan Pires, a lead author of the study, “With the new approach, there’s much less chance of any sort of operator mistake or mishaps. This is a process that can be readily implemented in GMP, and that’s really the key step here. We can create an innovation within the layer-by-layer nanoparticles and quickly produce it in a manner that we could go into clinical trials with.”

speed and Scale: The Numbers Speak for Themselves

The impact of this new technique is remarkable.The researchers can now generate 15 milligrams of nanoparticles – enough for roughly 50 doses – in just minutes. The previous method took nearly an hour to produce the same amount. “To scale up with this system, you just keep running the chip, and it is indeed much easier to produce more of your material,” Pires notes.

This newfound ability to rapidly produce large quantities of nanoparticles is essential for conducting extensive clinical trials and ultimately providing treatment to a significant number of patients.The implications for diseases like ovarian cancer, which often requires long-term treatment and monitoring, are particularly profound. The table below highlights the key benefits of the new microfluidic manufacturing process:

| Feature | Original Method | Microfluidic method |

|---|---|---|

| Production Time (for 15mg) | ~1 Hour | ~Few Minutes |

| Purification Steps | Required after each layer | Eliminated |

| GMP Compliance | Difficult and Costly | Easily Implemented |

| Scalability | Limited | High |

interleukin-12: harnessing the Power of the Immune System

To demonstrate the effectiveness of their new production technique, the researchers created nanoparticles coated with interleukin-12 (IL-12), a cytokine known for its ability to activate immune cells. Previous research from Hammond’s lab has shown that IL-12 delivered via layer-by-layer nanoparticles can effectively slow ovarian tumor growth in mice.

The latest study confirmed that IL-12-loaded nanoparticles manufactured using the new technique performed just and also those produced using the original method. Furthermore,these nanoparticles exhibit a unique characteristic: they bind to cancer tissue without entering the cancer cells. This allows them to act as signaling beacons, activating the immune system locally within the tumor microenvironment.In mouse models of ovarian cancer, this treatment has led to significant tumor growth delay and, in some cases, even complete cures.

this local activation of the immune system is particularly promising, as it minimizes the risk of systemic side effects that can occur with traditional immunotherapy approaches.

looking Ahead: Commercialization and Broader Applications

The researchers have filed for a patent on their technology and are collaborating with MIT’s Deshpande Center for Technological Innovation to explore the possibility of forming a company to commercialize the manufacturing process. While their initial focus is on cancers of the abdominal cavity, such as ovarian cancer, the technology has the potential to be applied to other types of cancer, including glioblastoma, a highly aggressive brain tumor.

The progress of this new nanoparticle manufacturing technique represents a significant step forward in the fight against cancer. By enabling the mass production of targeted drug delivery systems, this breakthrough could revolutionize cancer treatment, offering American patients more effective therapies with fewer side effects. the road to clinical trials and FDA approval is long and challenging, but the potential benefits for millions of people battling cancer are undeniable.