Mercedes to debut Lasting Carbon Fiber Composites in 2025 F1 Car

Table of Contents

- 1. Mercedes to debut Lasting Carbon Fiber Composites in 2025 F1 Car

- 2. The Composition of Sustainable Carbon Fiber

- 3. Rigorous Testing and Supply chain Collaboration

- 4. Beyond Motorsports: Applications in Aviation and Aerospace

- 5. Leadership Perspectives

- 6. The Future of Sustainable Materials in F1

- 7. what othre industries, besides aviation and aerospace, could benefit from sustainable carbon fiber composites?

- 8. Mercedes’ Sustainable Carbon Fiber Revolution: An Interview with Dr. Anya Sharma

- 9. The Science Behind Sustainable Carbon Fiber Composites

- 10. Rigorous Testing and Performance Standards

- 11. Beyond the Racetrack: Wider Applications

- 12. The Economic Viability of Sustainable Composites

- 13. A Question for Our Readers

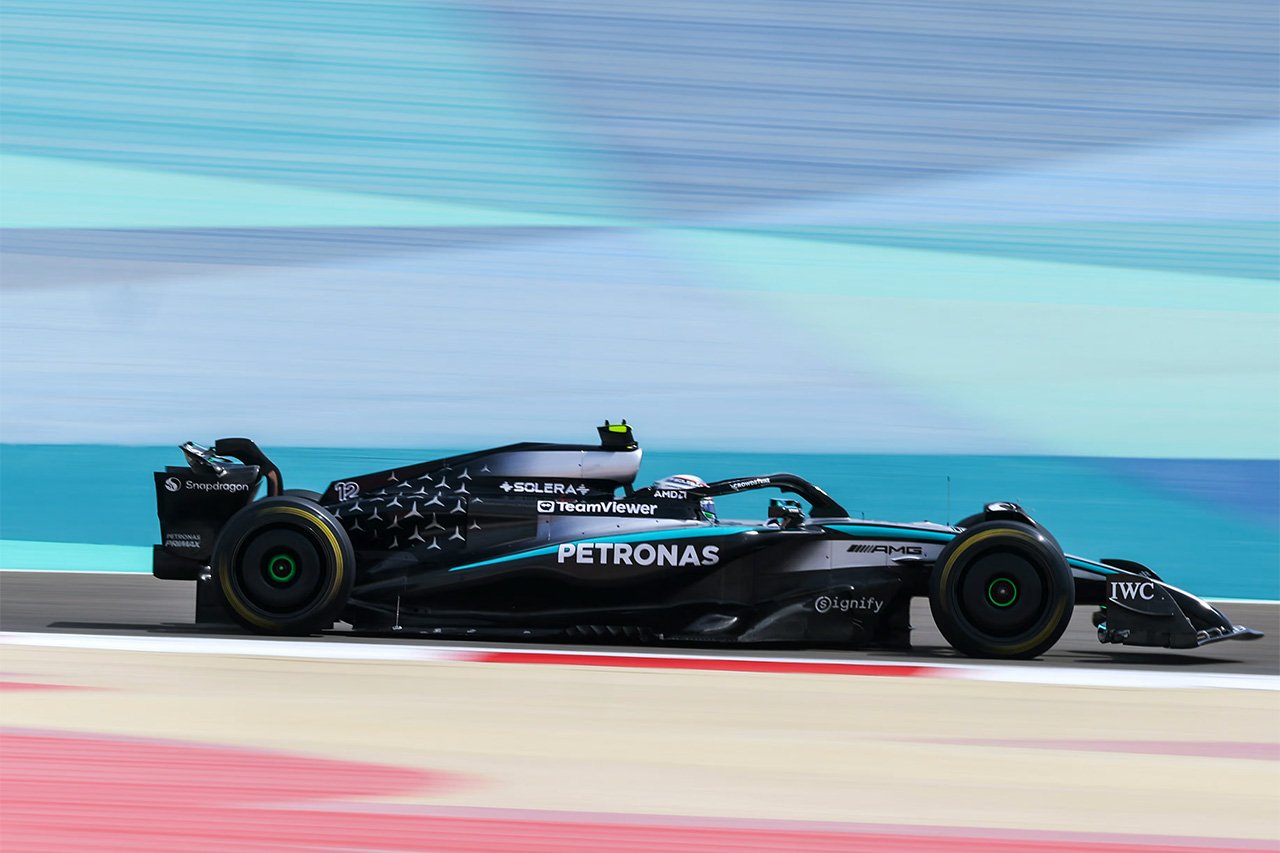

Mercedes is set to revolutionize Formula 1 with the introduction of sustainable carbon fiber composites in its 2025 W16 car. This pioneering effort marks a significant step toward reducing the team’s carbon footprint and achieving its goal of net-zero emissions by 2040.

The team must demonstrate to the FIA that these sustainable composites meet the same performance and safety benchmarks as conventional materials.

The Composition of Sustainable Carbon Fiber

Carbon fiber composites, crucial for both performance and safety, make up approximately 75% of a Formula 1 car’s materials.These composites primarily consist of:

- Fiber (approximately 60%)

- Resin system (approximately 40%)

Mercedes is tackling sustainability by focusing on both components through two projects slated for implementation by the end of 2025, according to the initial article.

Rigorous Testing and Supply chain Collaboration

Developing carbon fiber composites involves a complex supply chain, with each component requiring the involvement of four to eight suppliers. The team emphasizes the need for rigorous lab testing to ensure that the sustainable carbon fiber composites meet the stringent technical demands required for F1 racing.

Mercedes is working closely with the FIA to ensure compliance with all relevant regulations.

Beyond Motorsports: Applications in Aviation and Aerospace

Mercedes views this innovation as an prospect to develop sustainable high-performance materials with applications beyond motorsports.The team believes that these materials could be used in aviation, aerospace, and even technical performance fabrics.

Leadership Perspectives

Toto Wolff, team president and CEO, emphasized the importance of combining performance with sustainability: “When you combine performance and innovation, progress comes from it. I’m proud to lead a problem-solving team dedicated to bringing about sustainable change.”

Wolff also expressed gratitude to the team’s partners and the FIA for their support: “We would like to thank our partners for supporting our innovative efforts and the FIA for making it possible to test these materials.” He added, “We are working together to develop sustainable products, demonstrating that F1 will continue to be the fastest laboratory in the world.”

Alice Ashpitel, director of sustainability at Mercedes, highlighted the team’s commitment to sustainable innovation: “We are proud to be at the forefront of sustainable innovation in this sport.” Ashpitel further stated, “Leadership must be driven by innovation. Our team’s efforts in this field are the latest proof of our ambition to become one of the most sustainable global sports teams in the world. we look forward to exploring the request of sustainable materials this season.”

The Future of Sustainable Materials in F1

Mercedes’ initiative sets a new precedent for sustainability in Formula 1. This move is not only vital for reducing the environmental impact of racing but also for driving innovation in materials science. As Mercedes continues to develop and refine these sustainable carbon fiber composites, the entire industry could benefit from these advancements.

What do you think about Mercedes’ initiative? Share your thoughts in the comments below and join the conversation about the future of sustainable materials in motorsports!

what othre industries, besides aviation and aerospace, could benefit from sustainable carbon fiber composites?

Mercedes’ Sustainable Carbon Fiber Revolution: An Interview with Dr. Anya Sharma

Mercedes-AMG Petronas Formula One Team is pushing the boundaries of sustainability with its plan to introduce lasting carbon fiber composites in the 2025 season. This bold initiative aims to drastically reduce the team’s carbon footprint and paves the way for a greener future in motorsports. To delve deeper into the science and implications of this development, we spoke with dr. Anya Sharma,a leading materials scientist specializing in sustainable composites.

The Science Behind Sustainable Carbon Fiber Composites

Archyde News: Dr. Sharma, thank you for joining us. Could you explain what makes these carbon fiber composites “sustainable” compared to traditional materials used in Formula 1 cars?

Dr. Anya Sharma: Absolutely. Traditional carbon fiber composites rely heavily on petroleum-based resins and energy-intensive manufacturing processes. Mercedes’ approach is focused on two key areas: the fiber itself and the resin system. They’re exploring bio-based or recycled carbon fibers, reducing reliance on virgin petroleum. Equally notable is the resin system; replacing conventional epoxy resins with bio-derived alternatives dramatically lowers the overall carbon footprint.This addresses the composition of approximately 75% of what makes up the materials in the car.

Rigorous Testing and Performance Standards

Archyde News: F1 cars demand extreme performance. How can Mercedes guarantee these sustainable materials meet the same stringent performance and safety benchmarks as conventional materials?

Dr. Anya Sharma: That’s the million-dollar question. The key lies in rigorous testing and validation. Mercedes will be conducting extensive lab tests, simulating the stresses and strains experienced during a race. This includes impact resistance, tensile strength, and thermal stability. Moreover,working closely with the FIA is crucial to ensure compliance with all safety regulations. The team must prove unequivocally that these sustainable carbon fiber composites perform at the same level, or better, than the existing materials regarding safety. Their supply chain collaboration is also key to ensuring material consistency.

Beyond the Racetrack: Wider Applications

Archyde News: Mercedes sees potential applications for these sustainable materials beyond Formula 1, particularly in aviation and aerospace. Can you elaborate on this?

Dr. Anya Sharma: Absolutely. Industries like aviation and aerospace are constantly seeking lightweight, high-strength materials to improve fuel efficiency and reduce emissions. If Mercedes can successfully develop and validate these sustainable carbon fiber composites in the demanding surroundings of Formula 1, it opens up exciting possibilities for their adoption in these sectors. Imagine aircraft components, drone structures, or even high-performance sporting equipment utilizing these materials. The potential is vast.

The Economic Viability of Sustainable Composites

Archyde News: One concern surrounding sustainable materials is often their cost. Are sustainable carbon fiber composites economically viable compared to traditional options?

Dr. Anya Sharma: That’s a valid point. Initially, sustainable materials may have higher upfront costs due to the development and scaling of new manufacturing processes. however, as demand increases and production techniques become more efficient, costs are likely to decrease. Moreover, considering the long-term benefits, such as reduced environmental impact and potential cost savings from waste reduction and resource efficiency, sustainable composites can become economically competitive, especially when supported by policies and incentives.

A Question for Our Readers

Archyde News: Dr. Sharma, this has been incredibly insightful. a question for our readers: What other industries do you think could benefit most from the development of sustainable carbon fiber composites,and what challenges need to be overcome to facilitate their widespread adoption? Share your thoughts in the comments below!