Swiss Battery Firm Libattion Aims to Boost European Energy Security with New facility

Table of Contents

- 1. Swiss Battery Firm Libattion Aims to Boost European Energy Security with New facility

- 2. Expanding Battery Production in Europe

- 3. The Synergy of Recycling and Production

- 4. CEO’s Perspective: Meeting Market Demands and Conserving Resources

- 5. Safety First: Ensuring Reliable and Secure Operation

- 6. Building a European Center of excellence

- 7. Sustainable Growth Opportunities

- 8. What are teh notable enduring growth opportunities that you see for companies like Libattion?

- 9. interview: Dr. Anya Sharma on Libattion’s Impact on European Battery Storage

- 10. introduction

- 11. Expanding Battery Production and European Energy Security

- 12. Sustainability and Circular Economy

- 13. Safety and Innovation

- 14. Future Outlook

- 15. Conclusion

- 16. Reader Engagement

By Archyde News Journalist

Expanding Battery Production in Europe

In a move designed to bolster European energy security and reduce reliance on foreign raw materials, Libattion is aggressively scaling up it’s battery energy storage system (BESS) production. The company’s new facility in Biberist, Switzerland, is projected to reach an annual capacity of 500 MWh by 2026, with plans to eventually scale up to a full 1 GWh. This expansion positions Libattion as a key player in meeting the escalating demand for energy storage solutions across the continent.

The demand for reliable energy storage is surging, particularly in the U.S., driven by the increasing adoption of renewable energy sources like solar and wind. Battery storage systems play a crucial role in smoothing out the intermittent nature of thes renewables, ensuring a stable and consistent power supply. Consider California, for instance, which has invested heavily in battery storage to mitigate grid instability caused by periods of low solar output or high demand during peak hours. this proactive approach highlights the growing recognition of BESS as essential infrastructure for a modern, resilient grid.

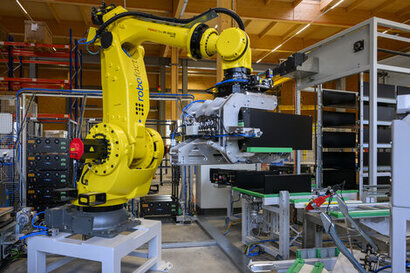

The Biberist facility, encompassing 7,000 square meters, leverages a high degree of automation to enable large-scale battery storage production. This automation is key to achieving both efficiency and cost-effectiveness. As evidenced by their production figures, Libattion has demonstrated consistent growth: 7 MWh produced in 2022, 12 MWh in 2023, and 27 MWh in 2024. The modular storage systems offer flexibility, ranging in capacity from 97 kWh to 60 MWh, catering to a diverse array of applications, from residential to industrial scale.

The Synergy of Recycling and Production

Adding a unique layer of sustainability and circular economy principles, the production site shares premises with Librec, a Swiss battery recycling company.this co-location creates regional synergies along the entire supply and value chain. The ability to recycle and reuse battery components locally drastically reduces the environmental impact of battery production and enhances the economic viability of the Biberist site.

This integrated approach provides a distinct advantage in a market increasingly focused on sustainability. The ability to reclaim valuable materials from end-of-life batteries closes the loop,reduces reliance on newly mined resources,and lowers the overall carbon footprint of BESS. In the U.S., similar initiatives are gaining traction, with companies like Redwood Materials leading the charge in battery recycling and materials recovery. However, the European model of co-locating recycling and production facilities offers a compelling blueprint for creating truly lasting battery ecosystems.

CEO’s Perspective: Meeting Market Demands and Conserving Resources

Stefan Bahamonde, CEO and co-founder of Libattion, emphasizes the importance of meeting growing demand while promoting resource conservation. “The demand for energy storage solutions continues to grow, and reusing EV batteries as stationary energy storage units unlocks huge potential for the European storage market,”

he stated. He further added, “Our new production hall allows us to respond flexibly to market demands while making a notable contribution to conserving resources in Europe. Thanks to automation,we can operate not onyl efficiently but also economically,and precisely scale our capacity to match demand.”

Bahamonde’s vision aligns with the broader global trend towards sustainable energy solutions. Repurposing EV batteries for stationary storage addresses two critical challenges: reducing battery waste and providing affordable energy storage. As electric vehicle adoption accelerates, the availability of used EV batteries will increase dramatically, creating a vast resource for second-life applications. This approach not only extends the lifespan of batteries but also reduces the environmental burden associated with manufacturing new ones.

Safety First: Ensuring Reliable and Secure Operation

Libattion places a strong emphasis on safety, implementing rigorous inspection processes and multi-layered safety systems throughout the battery lifecycle. Continuous monitoring is employed to ensure reliable and secure operation.

“Safety is paramount in our systems – through automated production and strict quality controls, we can guarantee the highest safety standards for every storage unit,”

Bahamonde affirmed.

In the U.S., safety concerns surrounding battery storage systems have been amplified by incidents involving fires and thermal runaway. These incidents underscore the importance of robust safety protocols and stringent quality control measures. The National Fire Protection Association (NFPA) has developed thorough standards for the installation and operation of BESS to mitigate safety risks. Continuous monitoring systems, coupled with advanced thermal management technologies, are crucial for preventing and detecting potential hazards.

| Safety Measure | Description | U.S. Equivalent |

|---|---|---|

| Automated Production | Minimizes human error during manufacturing. | Robotic assembly lines with quality control checks. |

| Strict Quality Controls | Ensures each battery meets performance and safety standards. | UL certification and self-reliant testing. |

| Continuous Monitoring | Tracks battery performance and detects potential issues. | Battery Management Systems (BMS) with remote monitoring capabilities. |

Building a European Center of excellence

the launch of the Biberist facility is a strategic effort to strengthen European battery production capabilities and enhance energy security. By co-locating with Librec, the project aims to create a regional center of excellence for battery technology, driving innovation and fostering economic growth in the region.

This initiative resonates with broader European Union efforts to establish a competitive and sustainable battery industry. The EU’s Battery Alliance aims to create a comprehensive value chain within Europe, from raw material sourcing to battery manufacturing and recycling. Investments in R&D, infrastructure, and workforce progress are critical to achieving this goal. The Biberist facility represents a concrete step towards realizing this vision, contributing to a more resilient and independent European energy system.

Sustainable Growth Opportunities

The increasing demand for energy storage presents significant sustainable growth opportunities, securing the site’s competitiveness on a global scale. The integration of recycling processes, the focus on safety, and the utilization of automation position Libattion for long-term success in a rapidly evolving market.

For U.S. companies looking to compete in the global energy storage market, the Libattion model offers valuable lessons. Investing in sustainable practices, prioritizing safety, and embracing automation are essential for building a competitive edge. Furthermore, fostering collaboration between industry, government, and research institutions is crucial for driving innovation and accelerating the deployment of energy storage solutions. As the world transitions towards a cleaner energy future, companies that prioritize sustainability and innovation will be best positioned to thrive.

What are teh notable enduring growth opportunities that you see for companies like Libattion?

interview: Dr. Anya Sharma on Libattion’s Impact on European Battery Storage

introduction

Archyde News: Welcome, Dr. Sharma. It’s a pleasure too have you. For our audience, Dr. Anya Sharma is a leading energy analyst specializing in sustainable technologies and currently advising several European governments on their renewable energy strategies. We’re hear today to discuss Libattion’s new facility in Biberist,Switzerland,and its potential impact.

Dr. Sharma: Thank you for having me. I’m happy to be here to discuss this exciting progress.

Expanding Battery Production and European Energy Security

Archyde News: Libattion is significantly scaling up its Battery Energy Storage System (BESS) production. how crucial is this for European energy security, especially given current global circumstances and the increasing demand for renewables?

Dr. Sharma: it’s incredibly crucial. Europe is actively seeking to reduce its reliance on external energy sources and transition to renewable energy. Battery storage is essential for stabilizing the grid with intermittent renewable sources like solar and wind. Libattion’s expansion significantly strengthens Europe’s ability to manage its energy needs independently.

Archyde News: The article mentions a potential annual capacity of 1 GWh. What kind of impact would such a production level have on the European market?

Dr. Sharma: Reaching 1 GWh would be a very significant addition to the market. It translates into enough storage to power many thousands of homes and businesses, allowing for more widespread adoption of renewable energy sources. This additional capacity aids in grid stability and can enhance cost savings from energy.

Sustainability and Circular Economy

Archyde News: Libattion’s co-location with a battery recycling company, Librec, is a fascinating aspect.How does this contribute to the circular economy, and what are the benefits?

Dr. sharma: The co-location is a game-changer. It creates a closed-loop system. Being able to recycle and reuse battery components locally drastically minimizes the environmental impact of battery production. It also enhances the economic viability of the Biberist site, making the entire process more sustainable and efficient.

Archyde News: How does the Libattion model compare to initiatives in the U.S., and what lessons can other regions learn?

Dr. sharma: The European model, with its integrated approach to production and recycling, offers some real advantages. While the U.S. has strong initiatives in battery recycling, the co-location strategy creates synergies we don’t see as often. It is a model of a truly lasting battery ecosystem that focuses on reducing mining, lowering the carbon footprint, and creating local jobs in the transition toward cleaner energy. This is a brilliant blueprint for the whole world.

Safety and Innovation

Archyde News: Safety is a significant consideration with battery storage systems. What is the significance of Libattion’s focus on safety, as highlighted in the article? Could you discuss the safety measures employed, especially when contrasted with concerns in the U.S. market?

Dr.Sharma: Safety is absolutely critical. Continuous monitoring, automated production, and strict quality controls are very critically important. In the U.S., we’ve seen incidents with battery storage, underscoring the need for robust safety protocols and stringent compliance. The measures employed by Libattion reflect growing awareness and focus on this extremely important aspect.

Archyde News: Automation is a key factor for efficiency. How does Libattion’s use of automation contribute to cost-effectiveness and scalability?

Dr. Sharma: Automation allows for higher production volumes while minimizing human error and labor costs. This leads to greater efficiency and, ultimately, lower prices for consumers. Automation also allows Libattion to precisely scale production to match market demands, which is crucial for responding to the rapidly evolving energy storage market.

Future Outlook

Archyde News: looking ahead, what are the significant sustainable growth opportunities that you see for companies like Libattion?

Dr. Sharma: The demand for energy storage is going to continue to grow exponentially. Libattion, by focusing on the integration of sustainable practices, safety, and automation, is well-positioned for long-term success. Initiatives like repurposing EV batteries also help with sustainability and growth in the evolving energy sector.

Archyde News: what one piece of advice would you give to U.S. companies looking to compete in the global market of Energy Storage Systems?

Dr. Sharma: I would advise the U.S. businesses to be aware of the sustainability and safety measures involved in Libattion’s method. In order to be competitive,one must collaborate on sustainability and automation.

Conclusion

Archyde News: Dr. Sharma, thank you for your insights. It truly seems Libattion’s expansion represents a very positive step for European energy security and the implementation of the circular economy.

Dr. Sharma: Thank you for having me. I believe it’s a very exciting time for energy storage technology.

Reader Engagement

Archyde News: We encourage our readers to share their thoughts on Libattion’s initiatives. Do you think co-locating battery recycling and production facilities is the future of sustainable energy? Let us know in the comments below!