:format(webp)/nginx/o/2025/04/26/16800069t1hb3da.jpg)

Old Riga Festival Returns This Saturday

Old Town Revival: Riga Festival Model for U.S.cities? April 26,2025 Revitalizing Historic Districts Through Arts and Culture Bar owners in Old riga are spearheading efforts

:format(webp)/nginx/o/2025/04/26/16800069t1hb3da.jpg)

Old Town Revival: Riga Festival Model for U.S.cities? April 26,2025 Revitalizing Historic Districts Through Arts and Culture Bar owners in Old riga are spearheading efforts

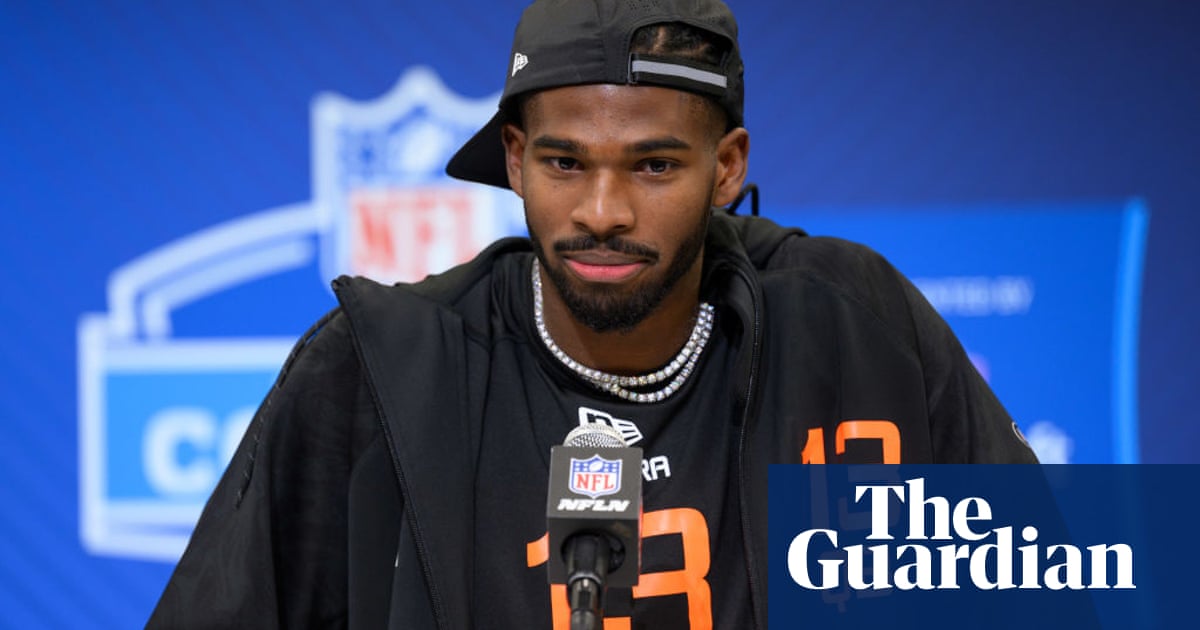

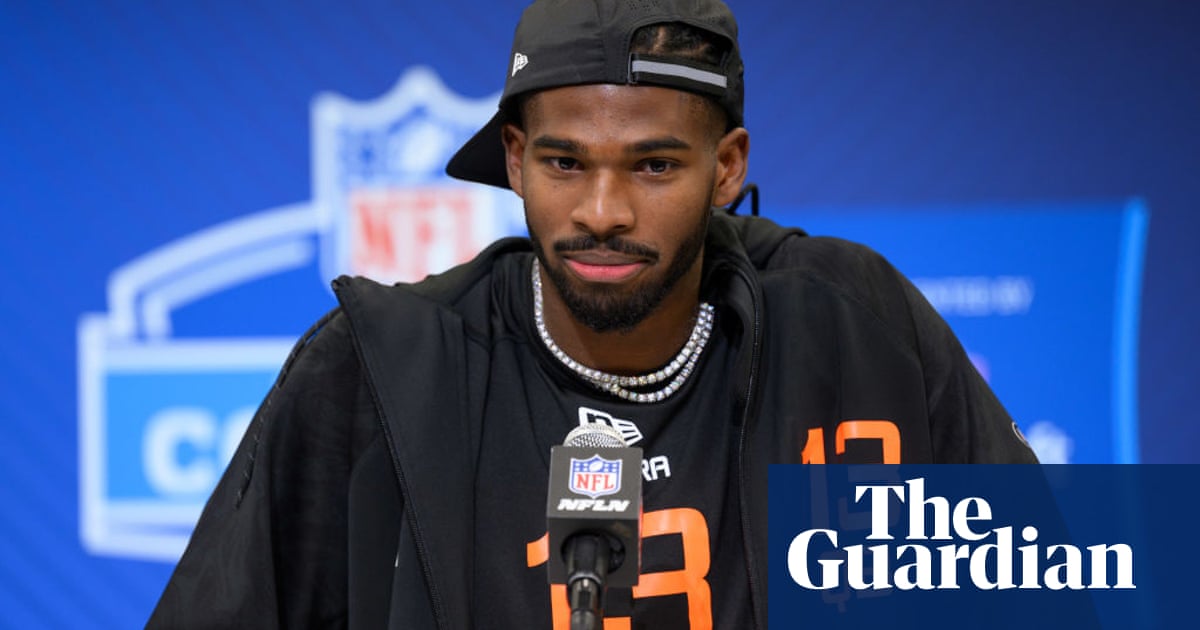

Shedeur Sanders NFL draft Slide: Why Was He Passed Over? The 2025 NFL Draft witnessed unexpected turns as Shedeur Sanders, once considered a top prospect,

Trisha Goddard’s Cancer journey: Thriving with Metastatic Breast Cancer TV personality Trisha Goddard is redefining life with stage four breast cancer,advocating for proactive symptom management

Shanghai Tourism Booms as China Eases Visa Restrictions; What It Means for US travelers Shanghai is experiencing a significant resurgence in international tourism, driven by

:format(webp)/nginx/o/2025/04/26/16800069t1hb3da.jpg)

Old Town Revival: Riga Festival Model for U.S.cities? April 26,2025 Revitalizing Historic Districts Through Arts and Culture Bar owners in Old riga are spearheading efforts

Shedeur Sanders NFL draft Slide: Why Was He Passed Over? The 2025 NFL Draft witnessed unexpected turns as Shedeur Sanders, once considered a top prospect,

Trisha Goddard’s Cancer journey: Thriving with Metastatic Breast Cancer TV personality Trisha Goddard is redefining life with stage four breast cancer,advocating for proactive symptom management

Shanghai Tourism Booms as China Eases Visa Restrictions; What It Means for US travelers Shanghai is experiencing a significant resurgence in international tourism, driven by

© 2025 All rights reserved